Describe:

Carbon fiber composite axle tube and metal axle head combination

Advantages:

1. High-strength carbon fiber structure, the weight of the carbon fiber axle tube is only 1/4-1/5 of the steel axle tube.Easier operation, lower risk of injury, reduced wear on mechanical components such as bearings, higher rotational speed, less deformation.

2. The strength of carbon fiber axle tube is higher than that of steel.Higher load-bearing capacity, more fatigue resistance, longer service life.

3. Save working time: It only takes about 3 seconds for the inflation and deflation to separate and place the coil tube, and the coil tube can be tightly gripped without disassembling any part of the shaft end side.

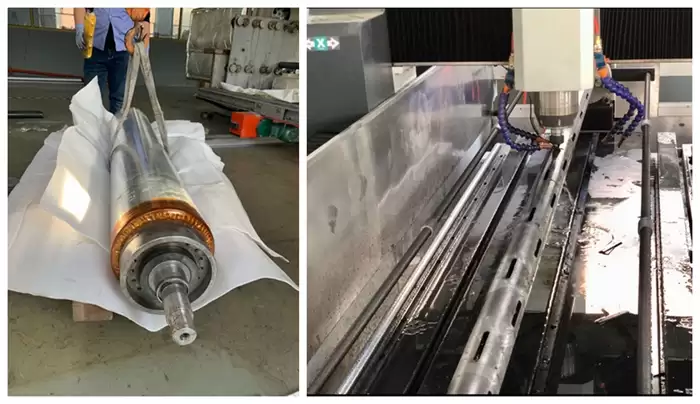

4. Winding molding process: Computer control, mechanized production, precise and unique winding angle, fiber preload.

How is the yarn laid?

All carbon fiber pipes are precisely wound from a single yarn by an automatic winding machine through a computer-preset program. Each type of tube corresponds to a separate yarn laying program, which precisely winds the carbon fiber at different angles, while the yarn tension and other corresponding parameters interact to achieve the required product bending curve. Only the precise angle winding solution of the yarn with preload provided by the winding process can perfectly solve the problem of the largest torque in the pipe application.