Carbon fiber tube has the advantages of high strength, wear resistance, corrosion resistance, light weight and so on. In addition, the product has a series of excellent properties such as relatively stable size, electrical and thermal conductivity, small coefficient of thermal expansion, self-lubrication and energy absorption seismic.

|

Product Name |

Custom Pre-preg Carbon Fiber Tube China |

|

Brand Name |

Future |

| Material | 100% Real Carbon fiber or hybrid with fiberglass/kevlar |

| Shape | Straight or Bending in Round or Angular Section |

| Specialty | -2005mm and small/large tube for wholesalers; -custom shaped tubes by drawing for end-users; |

| Advantages | -High quality with low factory cost; -Accumulated lots of moldings in stock; -Well managed production/logistic team with good service. |

| Features |

-High strength, fatigue resistance, corrosion resistance; |

Purchase by Shape:

About Future Composites:

A Chinese manufacturer dedicated to round and custom shaped carbon tubes, good at producing roll wrapped 2000mm length and 0.5mm thickness round carbon fiber tube with full size-molds supplying to wholesalers and molding compression shaped carbon tubes to end users. Thanks to customers support, and high quality with fast production time, fast logistics service, fast after-sales claim response service, Futures gained great development in the field.

4 Methods For Producing Carbon Fiber Tubes:

After years of accumulation, Future has followed the development of the industry. In order to meet the demands of different customers, Future has continuously upgraded its products and equipment. Currently, it has 6 autoclaves, 8 roll wrapping machines, 5 sets of molding equipment and 2 pultrusion lines. . Future’s engineers will formulate production plans according to the customer’s drawings/production costs/delivery time.

1, Roll wrapping

-Producing round straight tubes with high productivity and low production cost;

-Future is good at 2000mm long and 0.5mm thin & small tubes, with many mandrels in stock;

-We accumulated many carbon fiber tubes mandrels in 2000mm/3000mm for your wholesale business;

-For large diameter, the ID is up to 500mm ID, in 10meters long.

2, Molding compression

-Producing shaped and curved tubes, like oval, triangle, square, rec, hex, oct and curved tubes;

-Future’s engineer will design the lay up orientation and adopt the right fabric model to meet customers’ requirements;

-The molds in stainless steel can be produced in short time with cost-effective price.

3, Filament winding processing

What is the carbon fiber filament winding process?

The carbon fiber filament winding process is that the winding machine pre-sets the program through the computer, and a group of prepreg yarns are accurately prepared on the pre-designed circular mold to form a molding process with a high degree of mechanization of composite products. Each type of mast corresponds to a separate yarn laying program, which precisely winds carbon fibers at different angles, while the yarn tension and other corresponding parameters interact to achieve the required product bending curve. Only the winding process provides The precise angle winding solution of the yarn with preload can solve the huge torsion problem in the movement of the sailboat mast.

Dry filament wounding involves pre-impregnating carbon fiber bundles in resin and drying them to form pre-preg carbon fiber tows. During the wounding process, the pre-preg carbon fiber tows are heated to restore their tackiness and then directly wound onto the mandrel under tension control by wounding machine. Subsequently, curing and demolding are carried out. Since the carbon fiber tows materials are produced in advance, the resin content and fiber content can be precisely controlled. Additionally, the production equipment for dry filament winding has a relatively simple structure and is easy to operate. Therefore, the production efficiency of dry winding is high, the quality is stable, and it is suitable for the production of high-performance carbon fiber tubes.

Wet filament wounding involves passing the prepared carbon fiber yarn through a resin bath for impregnation, then guiding the impregnated carbon fiber bundles onto a mandrel via rollers, and finally curing and demolding. During the production process, it is essential to maintain a constant temperature and pressure in the resin bath and continuously stir it. Resin can also be changed according to different requirements. Depending on the application of carbon fiber tubes, the winding patterns can be classified into three types: helical winding, circumferential winding, and longitudinal winding. By applying these three winding patterns on different winding layers, the comprehensive tensile strength of the carbon fiber tube in both longitudinal and circumferential directions can be enhanced.

4, Autoclave machine

-Our autoclave machine produces carbon fiber tubes, sheets and custom parts;

-We produce carbon fiber square tube, rectangle tube, hex tube, oct tube by prepreg carbon fiber fabric in roll wrapped method, the mold cost is much less than mold pressing method, and the unit price is also low. We have many mandrels in stock, contact us now to check the list for you;

-The max inner side length of large carbon fiber square tube is 500mm x 5000mm;

All the carbon fiber products are made-to-order by customers requirements, for carbon fiber tube and sheet, small trial order is available to start business effectively. CNC machining service is possible for all the carbon fiber products by 3-axis, 4-axis and 5-axis.

FAQs for buying carbon fiber tubes:

MOQ: What is the MOQ of the carbon fiber tubes?

-The MOQ of carbon fiber tubes will be 10pcs, if the ID smaller than 50mm, for bigger ID, the MOQ could be negotiated.

Size: What is the largest diameter could you manufacture?

-The max ID diameter of carbon round tube is 800mmx8000mm, for square tube it is 500mmx500mmx8000mm.

Size: What is the smallest diameter of carbon fiber tube?

-The smallest inner diameter will be 2.5mm, 4x6x2000mm is one of our best-seller.

Size: What is the thickness of carbon fiber tube?

-1mm thickness carbon fiber tube has the largest output and highest production efficiency. We are also good at producing 0.23mm, 0.5mm, 0.7mm thin carbon fiber tube; and 2mm, 5mm, 10mm, 200mm thick carbon fiber tube.

Surface: What kind of surface treatment could you do?

-Glossy, 50% half glossy, matte, 50% half glossy, polished without painting, please contact our sales engineer for pictures.

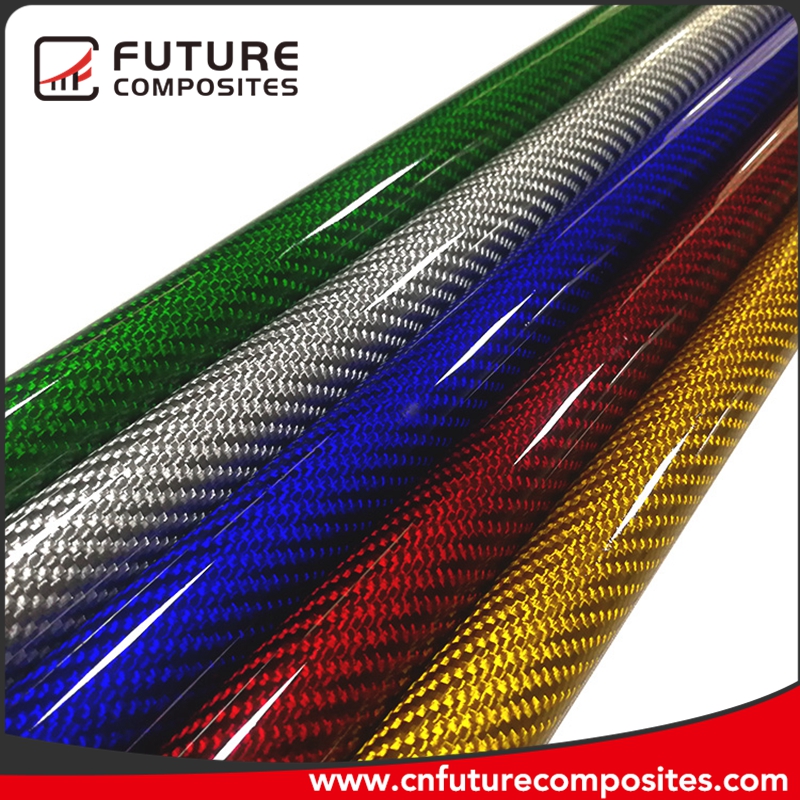

Colors & Patterns: What kind of color and patterns could you produce?

-We produce colored carbon sheet hybrid with kevlar fiber, in red, blue, green and so on. The colored Jacquard patterns and hybrid with electroplated fiberglass fiber in silver color are also available, reach out to our sales engineer to for more information.

Payment: What is the payment terms?

-50% pre-paypemt when placing order, balance and freight charge should be paid before shipment. Paypal, West Union & T/T are accepted, DAP/DDP/DDU delivery terms and other payment method should be negotiated.

CNC Machining: is it possible for CNC machining service?

-Yes, we could do by drawing. We introduced 2000x2500mm CNC machining facility, and 2000mmx3000mm water cutter machine to process ultra thick and ultra long carbon fiber tube.

Special offer: Most of carbon fiber tubes are made-to-order, To speed up quotations please please let us know clearly ID/OD/length and cnc machining work if needed.